RDF : Insight

Latest Dashboard data: up to end of February 2024.

Market-leading information and insight regarding the export of Refuse-Derived Fuels (RDF) and Secondary Recovered Fuels (SRF) from England to Europe, Scandinavia & further afield. Static reporting in PDF format is available as well as interactive, online supply chain reports.

If you would like to receive the one-page summary RDF Dashboard in your inbox every month, please add your e-mail address in the submission box at the bottom of this page.

What Is RDF?

Refuse derived fuel (RDF) is fuel created from certain types of residual, non-recyclable waste, such as municipal solid waste and other combustible refuse. This waste, usually taken from industrial or commercial sites, is shredded, dried, baled and then finally burned to produce electricity. The production of RDF is a responsible use of a sustainable energy resource, reducing fossil fuel demand. Furthermore, compared to the former practice of simply dumping unwanted waste in landfill and burying it, using the material to generate electricity and steam represents good stewardship of finite resources.

Shouldn’t The Waste Be Recycled Instead?

The RDF is produced from the residual waste stream; in other words, it is not created from the source-separated recyclables that households and businesses deposit in recycling bins. The residual feedstock undergoes various sorting and separation processes such as by weight (heavy items have a lower calorific value and won’t burn well). Metals are extracted using a magnet, while mechanical screening is used to remove the glass. After the screening stages, what remains is a lighter ‘fraction’ containing non-recyclable materials which may be food-contaminated, mixed polymer, dirty, sticky or unusable. In other words, RDF is what is left once all recyclables have been recovered.

Where Is RDF Used?

The UK does have the capacity to treat around 16 million tonnes of residual waste by incineration (again, even for the UK, the waste should go through the sorting, screening and separation processes to recover as much viable resource as possible). This incineration capacity has grown in recent years, with new ‘merchant’ facilities which can accept commercial and industrial feedstock. Inevitably, though, there is a balance to be struck: is it sensible to overshoot the waste volume with processing capacity, resulting in Energy from Waste (‘EfW’) sites being underused and inefficient? That is a risk, though the UK is not at that point yet. Presently, there is more waste feedstock than there is domestic EfW capacity to treat it, and so the ‘overflow’ is baled and sent to Europe and Scandinavia where there are Combined Heat & Power (‘CHP’) facilities that are both highly-efficient and hungry. These continental sites are typically linked to local heat networks, meaning that the steam is used to offset fossil fuel usage in local households or industries; this is in addition to energy production. By contrast, in the UK, the tradition has simply been to generate electricity and ‘lose’ the steam benefit … a less efficient method.

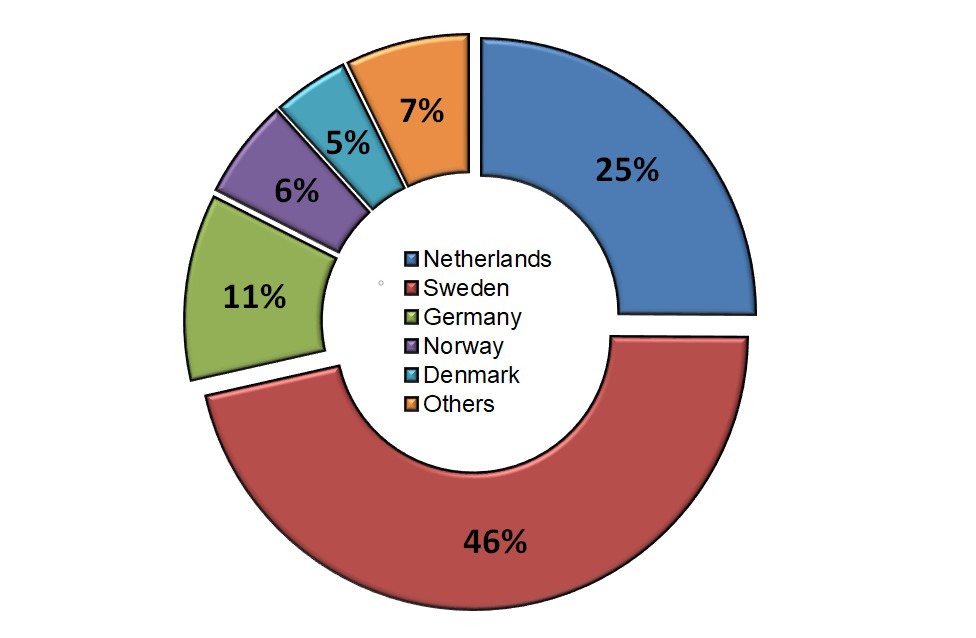

The chart below shows where the exported RDF heads to:

If you have any questions about RDF or SRF production in the UK or use, please get in touch.